N'èzí 3 Ọdụm mmanụ jụrụ ike Transformer

Njirimara ngwaahịa

1. Ọ bụ ihe ngbanwe na gburugburu ebe obibi na-enweghị obere ibu, enweghị ibu ugbu a na mkpọtụ.

2. Enweghị igbe nchekwa mmanụ iji chekwaa ohere.

3. A na-ekpuchi ya dum na mmanụ na-ekpo ọkụ, nkwụsi ike dị elu nke mkpuchi.

4. Na-anabata corrugations na tank mmanụ dị ka akụkụ ya ọkụ-radiation, corrugations nwere ike gbasaa ma ọ bụ nkwekọrịta nkwekọrịta na mgbanwe nke mmanụ.

5. Nhazi mechiri emechi, n'efu na-arụkwa ọrụ.

6. Na mmanụ larịị nlele iji hụ na nchekwa na-agba ọsọ.

Gburugburu Ọdabara

1.High ambient okpomọkụ: +40 ℃

2.Low ambient okpomọkụ: -25 ℃

3. Elu: <1000m

4. Nkezi iru mmiri kwa ọnwa: 90% (20℃)

5. Ebe nwụnye: Wụnye n'ebe ọkụ na-adịghị, ihe egwu mgbawa, mmetọ dị njọ, corrosion kemịkalụ na oké ịma jijiji, n'ime ụlọ ma ọ bụ n'èzí.

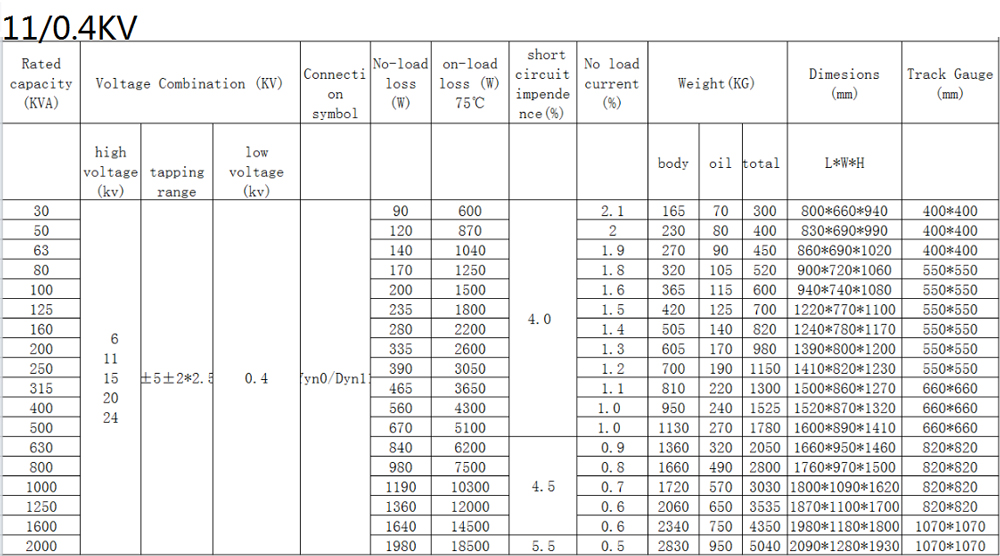

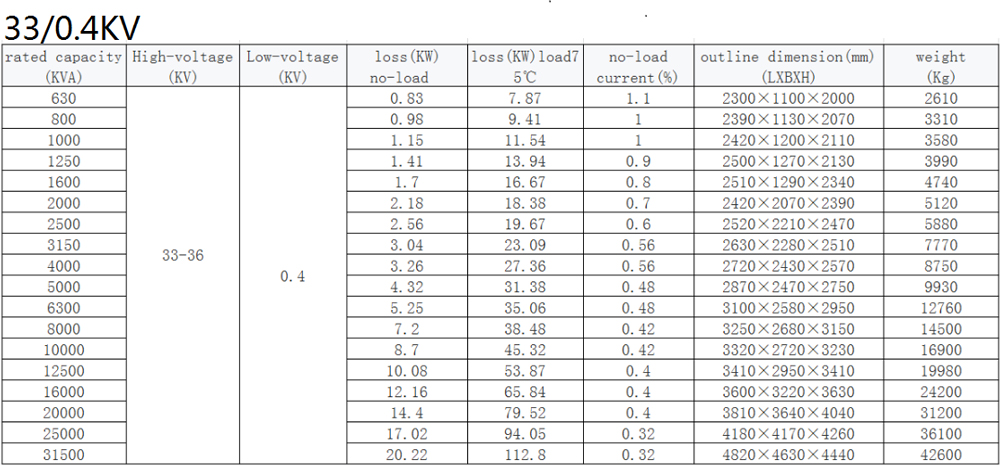

Ngwa teknụzụ ngwaahịa

Atụmatụ nhazi

| Nhazi ntụkwasị obi |

| Dabere na teknụzụ tozuru okè, anyị mere ọtụtụ ndozi na ndabere nke usoro ọdịnala: Igwe ikuku na-eji eriri mmanụ ogologo nke na-enwe ọfụfụ dị mma n'ime; Nkwenye nke nhazi ọkwa ọhụrụ na nhazi ahụ nke na-ekwe nkwa nchekwa na njem dị anya na ọrụ; Ọdịdị pụrụ iche na nke a pụrụ ịdabere na ya maka nhọrọ gị; Nkuchi nke transformers nwere arụmọrụ kachasị mma iji meziwanye ọdịnaya teknụzụ. |

| Ihe dị mma |

| N'ihi na anyị na-eji oxygen-free ọla kọpa wires nke ala resistivity, nke ga-aghọ smoother na burr-free mgbe a usoro nke elu ọgwụgwọ, otú ibu nke anyị transformer bụ ala na eletriki arụmọrụ ka mma.We na-eji elu àgwà silicon-ezu ohi Ibé akwụkwọ. nke bụ nke ala kpọmkwem ọnwụ, otú enweghị-ibu ọnwụ nke transformers bụ lower.We na-eji elu àgwà osisi laminating ikpuchi iberibe, nke na-agaghị kewaa ma ọ bụ na-akpali ọbụna n'okpuru mmetụta nke obere sekit ugbu a. Anyị na-eji mmanụ ngbanwe nke ọma nwere obere mmiri, gas ma ọ bụ adịghị ọcha, nke na-eme ka transformer anyị rụọ ọrụ nke ọma. Anyị na-eji ihe mkpuchi rọba dị elu, nke nwere ike igbochi transformers ịka nká ma ọ bụ ịgbapụta nke ọma. Ngwa ngwa niile agafeela ule dị mma, ụlọ ọrụ akụrụngwa niile agafeela nyocha ọkọlọtọ ISO9000 nke mba. |

| Ezi teknụzụ na arụmọrụ akụ na ụba |

| Emelitere site na ngwaahịa usoro S9, ngwaahịa usoro S11 na-ebelata mfu enweghị ibu site na 31%;enweghị ibu ugbu a site na 75-90%;nkezi ọkwa-ebili okpomọkụ site na 3-5 db;na okpukpu abụọ ndụ ọrụ ngwaahịa.Ọbụna n'okpuru ibu 20%, ọ nwekwara ike ịrụ ọrụ ogologo oge. |

| Emechiri ya nke ọma |

| "M" dị na S11 (M) na-anọchi anya nhazi nke omniseal nke tank mmanụ na-arụ ọrụ.N'iji ya na transformer na-emikpu mmanụ, omniseal mmanụ n'ime mmiri na-atụfu onye nchekwa mmanụ mana ọ na-anabata corrugation nke nwere nku maka dochie tube mmanụ dị ka akụkụ nke mgbasa ọkụ.A na-emepụta tankị mmanụ corrugated nke a na-eji akwa oyi akwa na-emepụta na ahịrị mmepụta pụrụ iche.The nku-dị ka corrugation ga-amụba na mpikota onu dị ka na olu nke transformer dose, nke mere na transformer kewapụrụ nke ọrụ na ikuku na ike igbochi ma ọ bụ nwayọọ nwayọọ na-emebi mmanụ na iku ume nke mkpuchi.Ihe ndị a niile na-eme ka ntụkwasị obi nke ịrụ ọrụ na enweghị mmezi. Mgbe ọgwụgwọ nke ịzụ ahịa, derusting na parkerizing, n'elu nke corrugated mmanụ tank na-ekpuchi ya na agba nke na-enye ọrụ akaebe atọ, ọ dị mma maka ojiji na gburugburu ebe obibi dị ka metallurgy. , petrochemical ụlọ ọrụ na Ngwuputa, wdg. |

Mbukota & Mbupu